Production Process

Beer production is a natural process that has been going on for thousands of years.

Beer production procedure has the following 4 main phases:

- Malting

- Brewing

- Packaging

- Storage & distribution

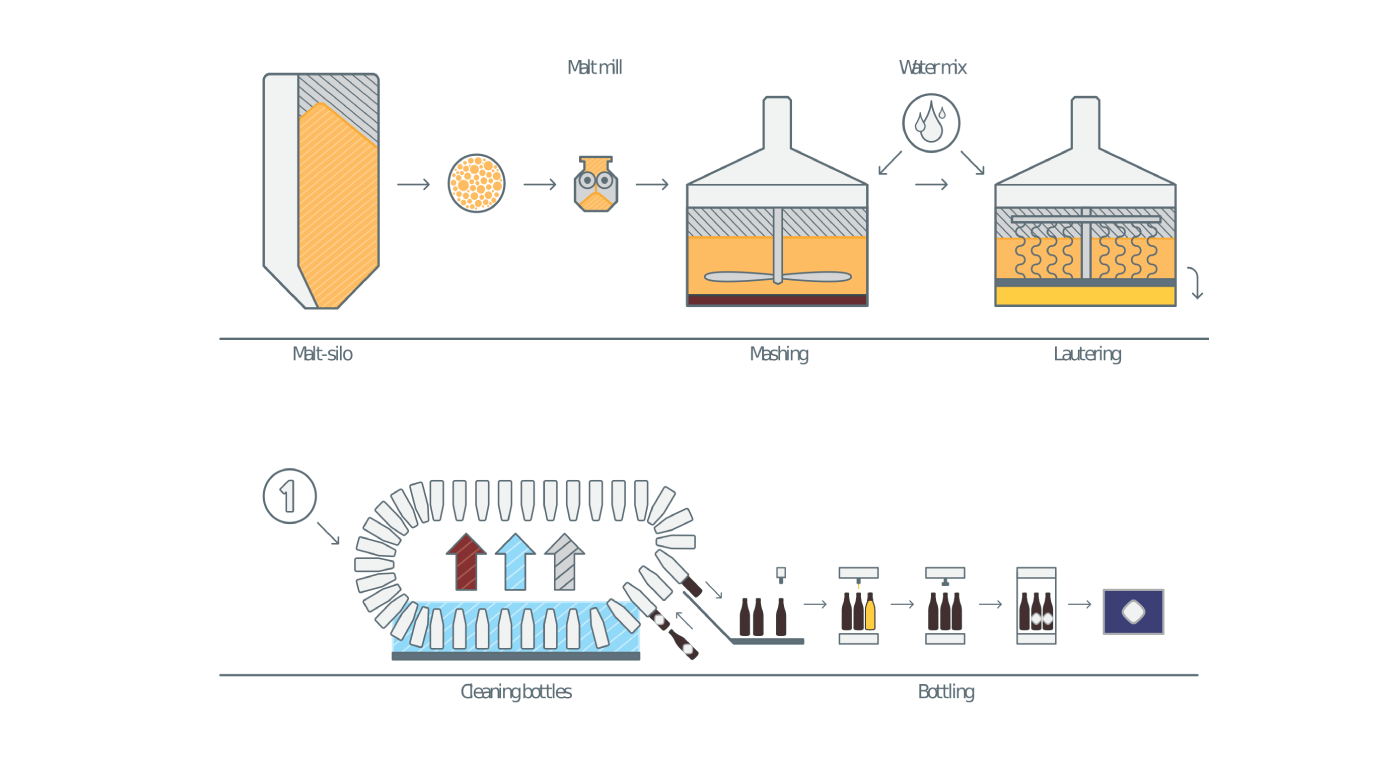

In the following diagram you can see each phase of the beer production process:

*at the bottom of the page you can find the production process of alcohol-free beer (AFB).

Malting

Malting, the process of converting barley into malt, produces enzymes required to break down and convert the barley content from insoluble (starch & protein) to soluble (amino acids). There are 3 main steps in malting process:

- Steeping

Water/air is added until barley moisture content rises up to 45%.

- Germination

Fresh air is supplied, and barley remains for 5 days at 12-16°C. Germination allows the development of useful malt enzymes, including amylase and protease.

- Kilning

Hot air at 80°C is supplied to deactivate enzymes and produce the malt color and aroma. Moisture content is gradually reduced from 45% to 4%.

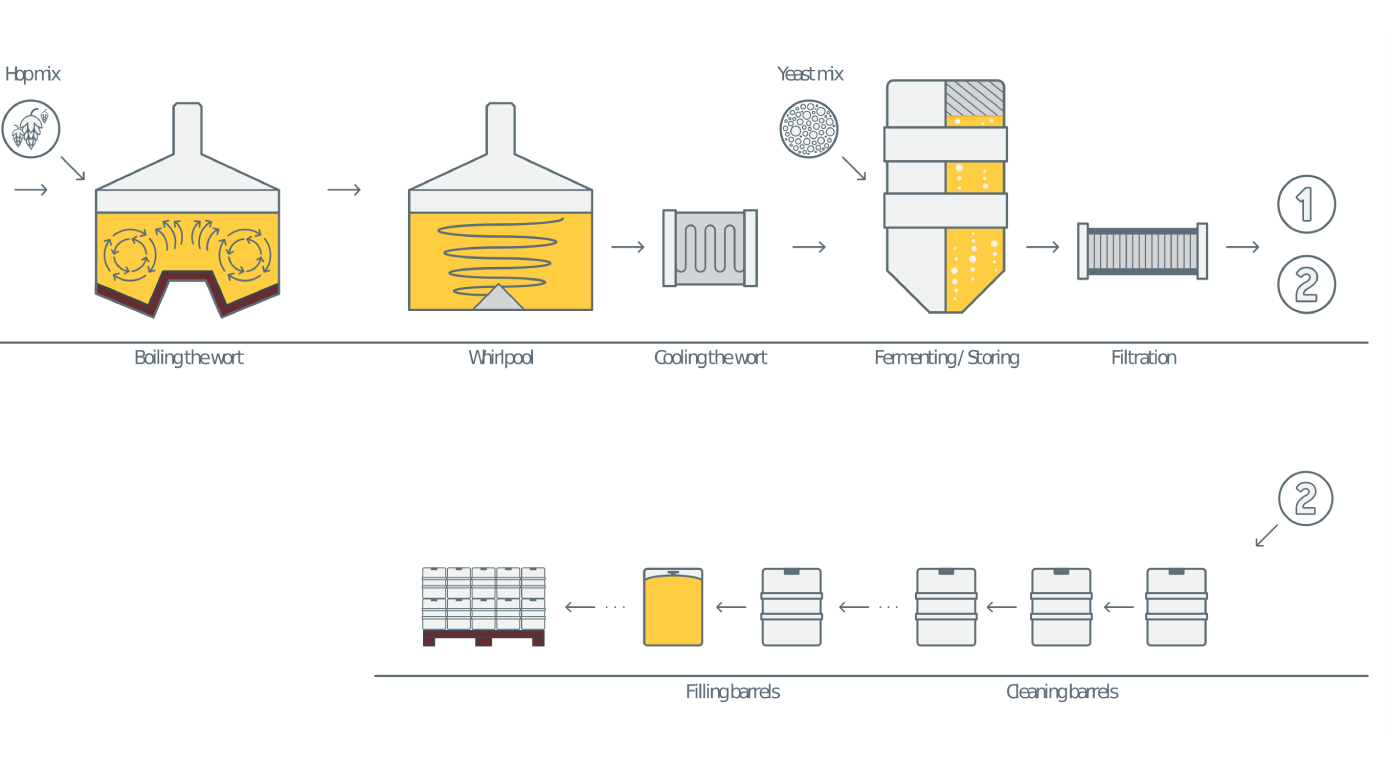

Brewing

The brewing process includes 6 important stages:

- Mashing

The process of milling malted barley and mixing it with water in a vessel called mash tun with a heating mantle to regulate temperature. The end product of mashing is called wort.

- Lautering

After mashing, the wort is separated from the grains to get a clear liquid wort. Lautering takes place in vessels known as lauter tuns, with thin slits at the bottom and a stirring system with rotating cutting blades. During this process, a grain bed settles on the bottom of the tun, composed of malt hulls and undiluted subsiding proteins. This bed is the main filtering medium during the separation process.

- Boiling

After lautering, the wort is boiled. This is a very important process where the following reactions take place:

- Sterilization of the wort.

- Stopping of enzymatic processes.

- Color development and releasing of aromas and flavor.

- Concentration of the wort due to water evaporation.

- Isomerization and extraction of compounds contained in hops.

- Formation and submersion of protein – polyphenol complexes.

- Volatile unwanted substances (e.g. DMS) are removed, to deliver a more solid flavor.

- Hop residues and coagulated proteins are separated from the boiled wort through a swirling and settling system. The clear liquid wort is cooled down through a plate heat exchanger and driven towards a fermenting vessel.

- Fermentation

After the wort is cooled and aerated, yeast is added to it, and the fermentation process begins. Fermentation takes place in fermenting vessels, under regulated temperature and pressure. During this process, which lasts from 5 to 9 days, the yeast converts sugars from the wort into alcohol and carbon dioxide. When fermentation is complete, the yeast settles at the cone of the vessel, it is collected and reused for the next brew. The produced carbon dioxide is collected, deodorized, condensed and liquidized, and then stored to be used in beer carbonation.

- Conditioning (Maturing/Aging)

Conditioning gives beer its final distinct flavor. During conditioning beer is stored at near freezing temperatures (0 to -1°C) and a secondary fermentation takes place, which improves immature beer, increasing its carbon dioxide concentration.

- Filtering

Before packaging, beer must be filtered to remove any yeast residues and substances that compromise beer quality over time. During filtering, the exact concentration of carbon dioxide and the beer final density are also regulated, and bright beer is stored in containers called bright beer tanks.

Packaging

Beer is packaged in three forms: bottles, aluminum cans and kegs. The packaging process includes 4 steps:

- Washing bottles/kegs or rinsing cans

- Filling

- Pasteurization

- Labeling

Storage

After packaging, beer is stored in conditions that ensure its high quality and then distribution takes place.

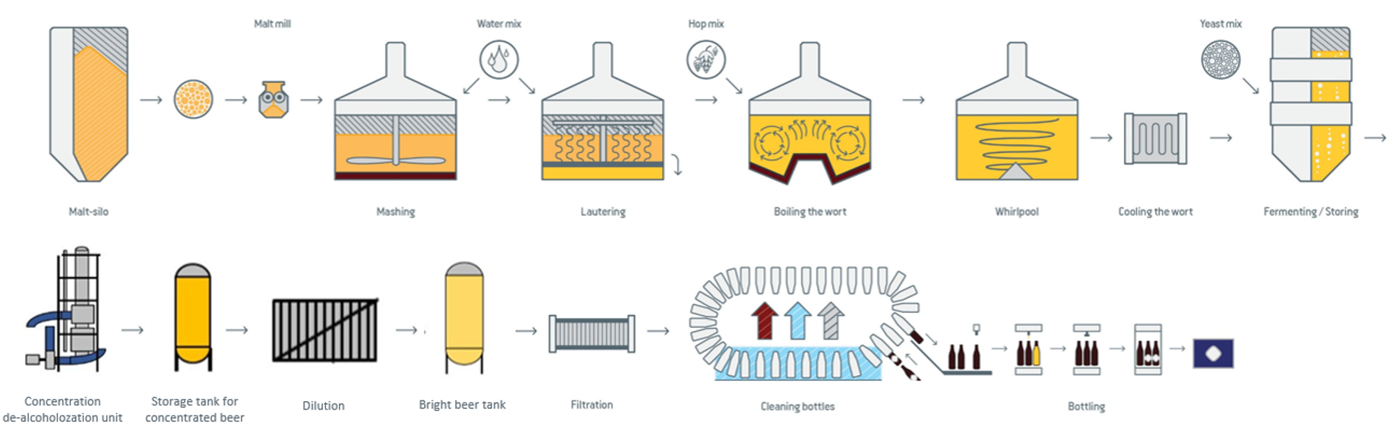

The production of alcohol-free beer (AFB)

The production of AFB comprises the same steps as beer production (malting, brewing, packaging and storage), with the following variations:

- Alcohol removal and beer concentration, as beer is transferred from maturation tank to concentration and de-alcoholization unit.

- Beer dilution, where concentrated beer without alcohol is diluted with deaerated water to its final physico - chemicals characteristics.

- Final beer filtration.

Central & Eastern Europe and India

-

Azerbaijan

-

Belarus

-

Bulgaria

-

Canada

-

Croatia

-

Estonia

-

Greece

-

Hungary

-

India

-

Italy

-

Kazakhstan

-

Latvia

-

Lithuania

-

Serbia

-

Ukraine